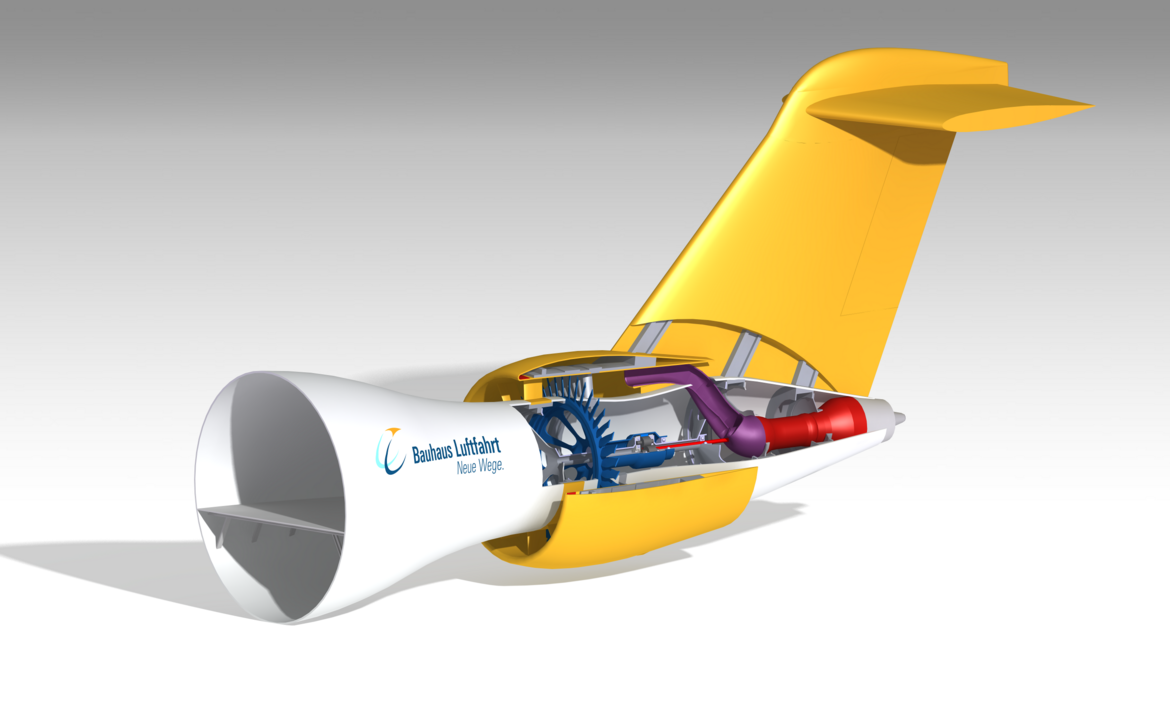

Novel approaches to the design and integration of propulsion systems are needed to further improve the efficiency of future aircraft. One promising degree of freedom that is repeatedly discussed in science and industry is to strategically distribute the power generated on board an aircraft to several fans. The model illustrates an early version of a ‘propulsive fuselage’ concept based on a mechanical drive of the ‘fuselage fan’ through a dedicated gas turbine in the rear fuselage.

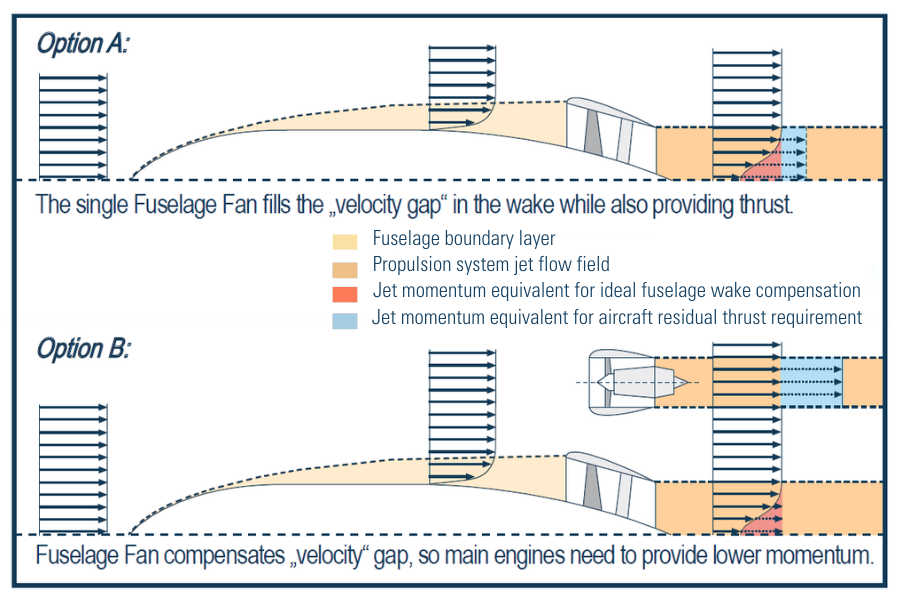

An increased fan face area for a given fan diameter and weight would significantly increase the propulsive efficiency. But such a ‘distributed’ propulsion system could also enable further synergies with the airframe – such as reduced structural loads, improved noise shielding and increased functional redundancy. A particularly attractive possibility arises from the use of the so-called ‘wake-filling’ effect. As has long been known from marine propulsion integration, the necessary power supply to the propulsive device can be significantly reduced by ingestion and re-acceleration of the fuselage boundary layer. Together with international partners in the DisPURSAL (Distributed Propulsion and Ultra-high bypass Rotor Study at Aircraft Level) project, the Bauhaus Luftfahrt team had been working on models to quantify the potential of such propulsion system integration at the overall aircraft level, back in 2013.

Less power demand for the same propulsive performance

One of the most promising options for a ‘distributed’ drive system is the use of a single fan encircling the rear section of the aircraft fuselage. The resulting ‘propulsive fuselage’ maximizes the potential of boundary layer ingestion and aircraft wake filling. The ‘fuselage fan’ thereby ensures that the aircraft leaves significantly less unused flow energy in its wake. As a result, the power demand for a given propulsive performance is reduced.

Ten per cent greater range compared to reference aircraft

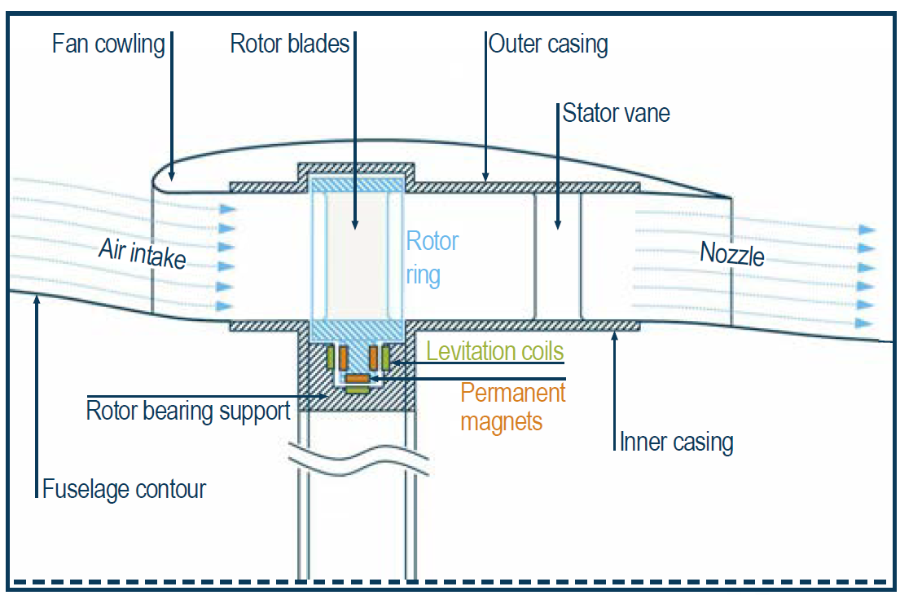

Initial analyses of the mechanically driven ‘propulsive fuselage’ concept from 2013 already showed a range increase of just over ten per cent compared to an advanced but conventionally powered twin-engine reference aircraft - despite the additional engine. The assessment also took effects into account that are expected to have an adverse efficiency impact, such as a reduced ram pressure recovery and fan inlet performance degradation resulting from the non-uniform in-flow when ingesting the fuselage boundary layer. A positive side effect however was that the two conventional engines primarily responsible for thrust could be designed to be smaller, lighter and more aerodynamic. The great aero-structural integration challenges due to a mechanical ‘fuselage fan’ power train could be alleviated by advanced electric drive options.