The decarbonization goals set by the European Commission led to various studies proposing to use fuel cells to power electric engines of higher capacity (80 < passenger < 250), short-, and medium-range aircraft. In this context, high-temperature polymer electrolyte fuel cells

(HT-PEFC) are gaining considerable attention due to their potential for notable advantages over low temperature (LT)-PEFCs at an aircraft system level.

Toward zero-emission nextgeneration

HT-PEFC aircraft.

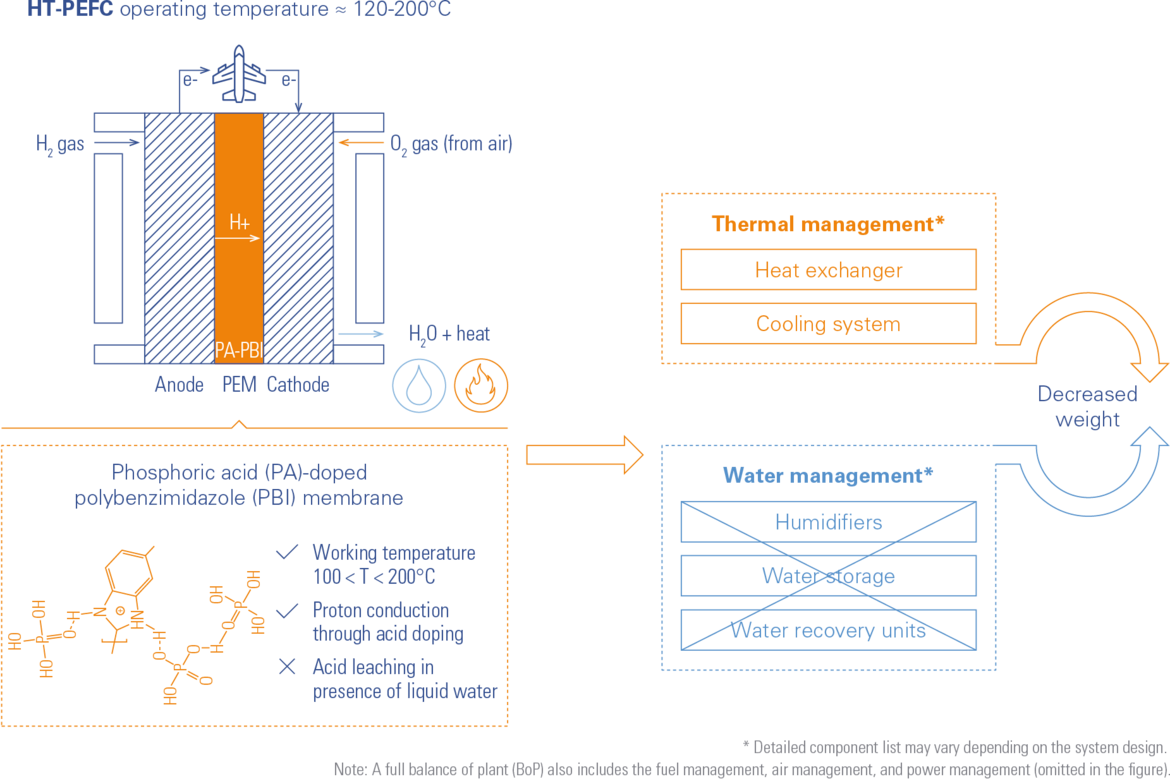

Bauhaus Luftfahrt analyzed the key technology advances and improvement potentials of HT-PEFCs. Their higher operating temperature, ranging from 120 °C to 200 °C, enables efficient heat dissipation and enhanced energy recovery, allowing a more effective and lighter thermal management system. Furthermore, operating at higher temperatures enhances reaction kinetics and improves tolerance toward contaminants (e. g. CO, H2S).

Proton conduction is typically achieved via polybenzimidazole (PBI) polymer membrane doped with phosphoric acid (PA). This allows the use of dry gases, eliminating the need for a humidification system and thereby reducing the overall system weight and complexity. Although PBI-PA membranes offer great benefits, they encounter challenges such as acid leaching in the presence of liquid water and reduced mechanical strength caused by the excessive doping, which reduces the durability and the electrode power density.

Despite these drawbacks, significant advancements over the past decade have addressed these issues (e.g. membrane electrode assembly (MEA)), allowing operation over a wide range of conditions. This progress positions HT-PEFC as a promising candidate for powering next-generation aircraft.

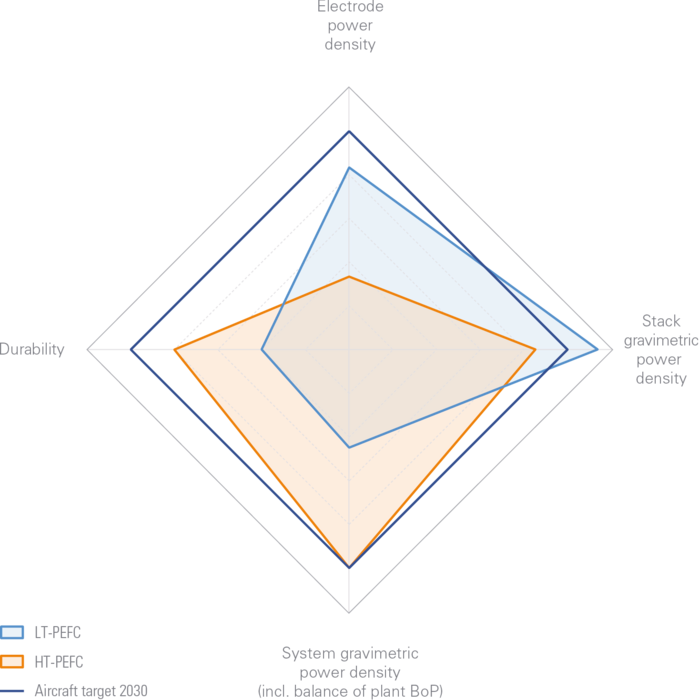

Comparison between LT-PEFC and HT-PEFC technologies

At elevated operating temperatures, HT-PEFCs facilitate thermal and water management due to their ability to operate under anhydrous conditions.

Comparison between LT-PEFC and HT-PEFC technologies

Despite the currently still inferior electrode power densities, HT-PEFCs show great advantage in the system gravimetric power density and durability (allegedly up to 20,000 hours [1,2]) in aeronautical conditions, thanks to significant advances in the membrane electrode assembly development.

Data based on:

[1] HyPoint Inc. White paper 2021 (HyPoint acquired by ZeroAvia in 2022).

[2] ZeroAvia, White paper, Scaling Hydrogen Electric Propulsion for Large Aircraft, 2024.

[3] EU Clean Hydrogen Joint Undertaking, Fuel cells and Hydrogen 2 Joint Undertaking,

Addendum to the Multi-Annual Work Plan, 2020.

Glossary: HT-PEFC high temperature polymer electrolyte fuel cell, LT low temperature, CO carbon monoxide, H2S hydrogen sulfide, PBI polybenzimidazole, PA phosphoric acid, MEA membrane electrode assembly