Structural health monitoring (SHM) using sensor networks makes it possible to reduce the manual inspection costs of aircraft. These costs depend both on components and on usage, and increase with aircraft age. As dedicated SHM systems increase aircraft weight and electric power demand, it is of interest to assess firstly, for which specific components monitoring might be worthwhile, and secondly, whether retrofitting later in life allows for higher savings as compared with pure factory instrumentation.

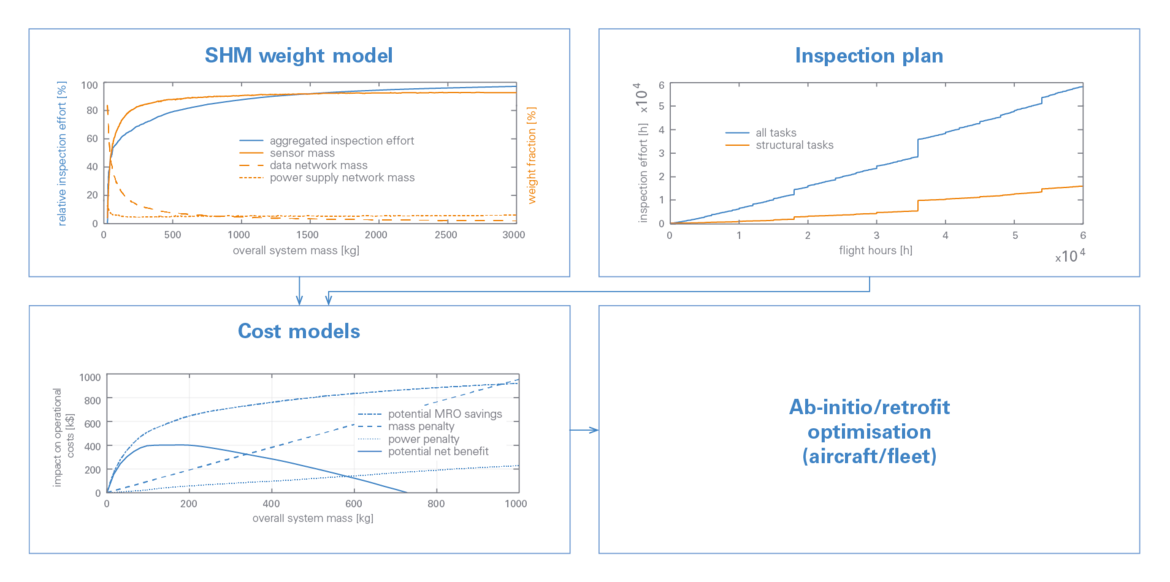

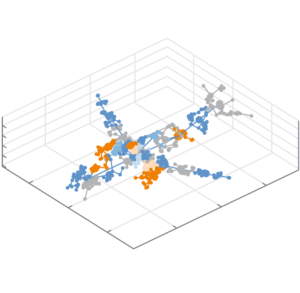

In order to address these questions, the influence of SHM coverage ratio and time of instrumentation was investigated in the framework of net present value (NPV) theory, using the A320 as an example. To this end, a sensor network model was developed based on individual structural components to contrast added investment and fuel costs with saved inspection effort for different aircraft usage.

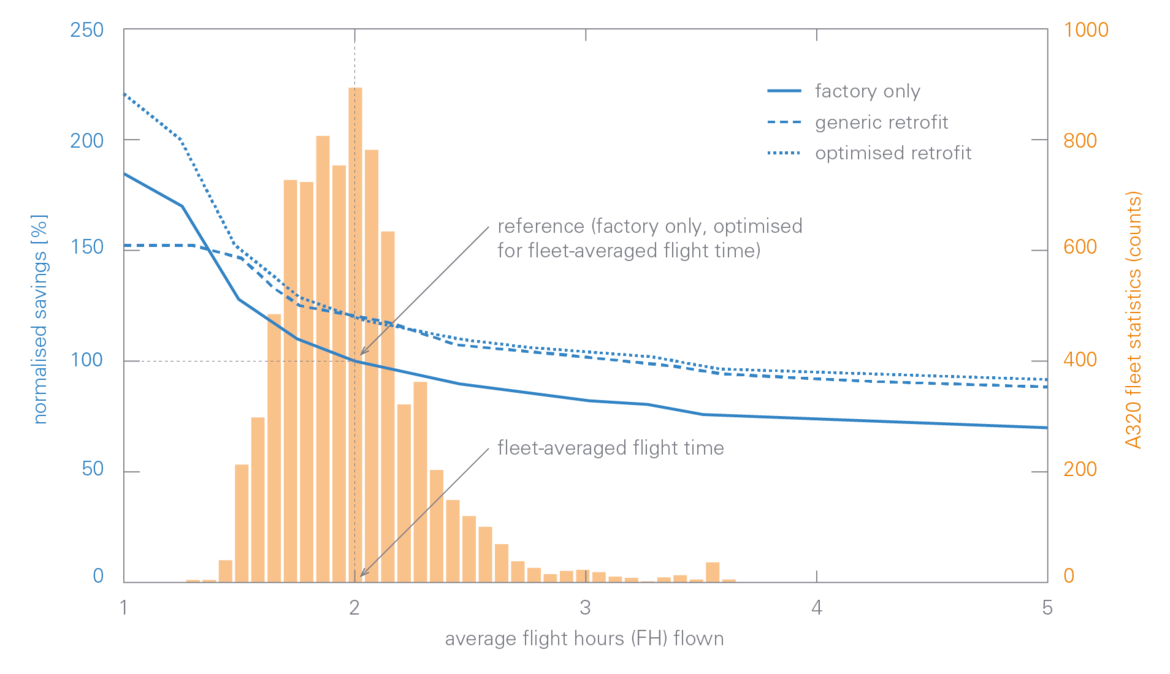

In this way, optimised SHM configurations were derived, which generally offer savings potential at aircraft level. Compared to pure factory instrumentation, a retrofit event later in life provides a 20 % advantage, as inspection effort and thus the benefit of the sensor system increase with aircraft age. Moreover, for aircraft operating on short-haul routes, SHM exhibits the largest savings potential. At fleet level, therefore, especially for airlines with a large share of short-haul flights, additional benefits arise if the retrofitting time and number of monitored positions are optimised for individual aircraft in accordance with their average usage.

Potential of pure factory instrumentation compared to retrofit options, considering aircraft usage

An “optimised retrofit” considering aircraft usage is always significantly better than a “factory only” instrumentation, whereas a fleet-like retrofit (“generic retrofit”) is not for short haul, but at fleet level.

Buechter, K.-D., & Koops, L. (2021). Retrofitting Potentials in Aircraft Structural Health Monitoring – A Value of Information Analysis. 13th International Workshop on Structural Health Monitoring. Stanford, United States.

Buechter, K.-D., Sebastia Saez, C., & Steinweg, D. (2021). Modeling of an aircraft structural health monitoring sensor network for operational impact assessment. Structural Health Monitoring, 21(1), pp. 208–224. doi:10.1177/14759217211048149