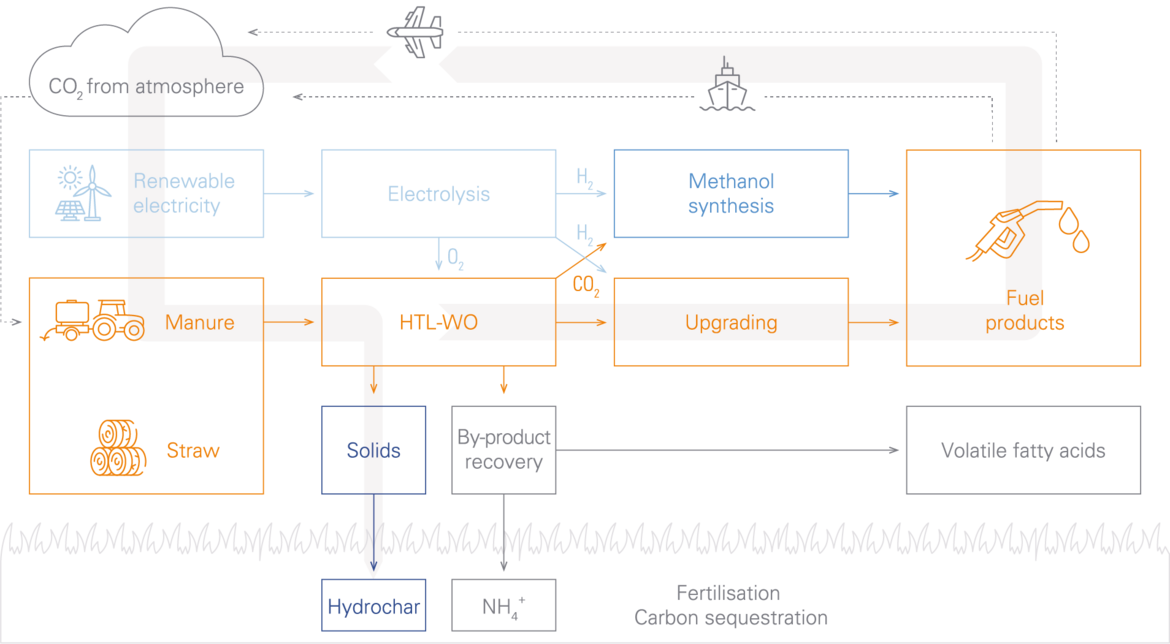

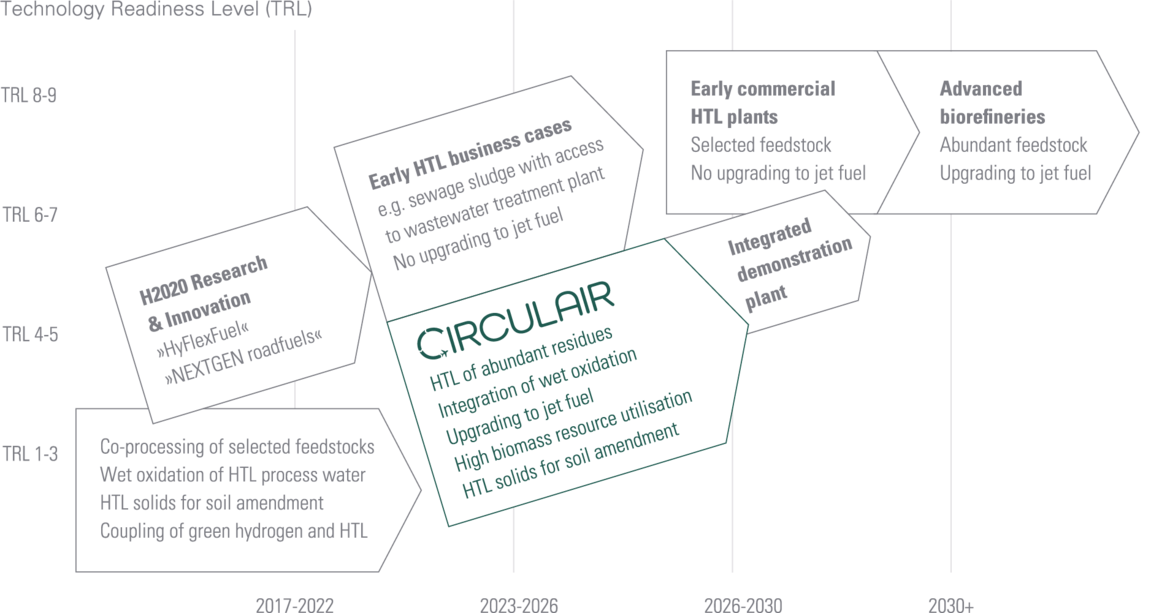

Biofuels only count towards the ReFuelEU aviation quota if they are produced from advanced feedstock. Leading European partners from academia and industry have joined forces to develop an innovative fuel conversion scheme within the EU-funded research project CIRCULAIR (2023 – 2026). The key conversion step, hydrothermal liquefaction (HTL), can convert various organic materials into fuels and is in particular suitable for wet feedstock. Manure and straw were chosen due to their high abundance in agriculture.

CIRCULAIR’s innovations cover the entire process chain from feedstock to final fuels and co-products. The challenge of process water handling, a major hurdle to HTL commercialisation, is addressed by integrating HTL with the exothermic wet oxidation (WO) process. WO cleans up the process water and provides heat to HTL conversion.

Further innovations include upgrading processes that yield a high share of jet fuel from HTL biocrudes and valorisation schemes for all relevant side streams to ensure high biomass utilisation. In particular, effluent CO2 streams are utilised for methanol synthesis and the suitability of HTL chars for soil application is investigated.

Bauhaus Luftfahrt coordinates the project and leads the system analyses within CIRCULAIR towards multiple key objectives: to explore the potential for low-cost biofuel production from abundant residues, to quantify the benefits of coupling HTL with green hydrogen, and to evaluate potential negative contributions to the greenhouse gas balance. The latter is enabled by soil application of HTL chars and emission avoidance resulting from a replacement of current manure-handling practices.